Some references

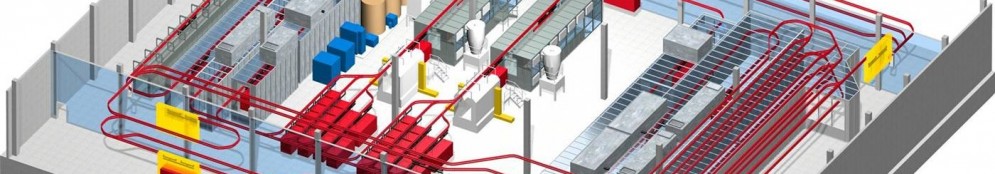

Ansova, Wehl (Nl)

Feasibility study, engineering, consultancy, projectmanagement etc. etc. for a complete new coatingplant (blasting and 2 layers powdercoating) for XXL heavy steel-construction parts.

The complete proces - blasting + application of primer+ gel-curing of the primer + application of the topcoat and curing - is done in just one time WITHOUT any extra handling needed.

Part dimensions up to 25 m. long x 3 m. high x 1.5 m wide.

Allowable parts-weight 10,000 kg. Total plant capacity over 60 tons of steel/hour

- Pass-through steel blasting machine with 20 turbines

- Double dedusting and cleaning booth

- 2 off powder-coating booths and -recovery-systems, each equipped with 36 Powder-guns,

- 2 off powder-ovens, each quickly adaptable to different heating sources like natural gas, propane or hydrogen

- Plant completely executed according industrial standard 4.0

- Great number of energy saving measures including heat-recovery en re-use of energy

- Extremely complex and heavy P+F conveyor system.

Staalcoating Van Merksteijn, Raalte

Feasibility study, engineering, consultancy, projectmanagement etc. for a complete new coatingplant (blasting/powdercoating) for heavy steel-construction parts.

Part dimensions 25,000 long x 2,500 high x 1,000 wide.

Weight up to 8,000 kg

- Pass-through steel blasting machine with 16 turbines

- Dedusting and cleaning booth

- Poederbooth and -recovery,

- Powder-oven,

- Cooling zone,

- Plant completely executed according industrial standard 4.0

- Great number of energy saving measures including heat-recovery en re-use of energy

- Complex P+F conveyor system.

Rotocoat Wolvega

Optimization of an existing pretreatment- and powder-coating plant;

- Design, and projectmanagement for the renewal and expansion of an existing line with complete new conveyor system, ovens en powderapplication equipment.

- Result: an increase in capacity of over 60%.

- In the new situation improvement of logistics and labour circumstances thus resulting in an higher efficiency.

- The complete turn-over took place in the existing hall within a period of not more than 8 weeks.

Koninklijke Auping, Deventer

Design and projectmanagement for a complete new pretreatmen- and powder-coating plant for domestic beds in a new-build factory.

- 5-Zones pretreatment plant,

- 2 Powderbooth and -recovery systems,

- Dryer, oven and cooling-zones executed as one combined unit, installed in the higher part of the hall. Result: less energy consumption and no loss of valuable floor-working space.

- series of measurements taken in order to reduce and recycle energy. Result: the dryer needs almost no external energy-input anymore.

- Complex P+F conveyor system

Alural Group, Lummen (B)

Projectmanagement at installing a completely new line for the powdercoating of vertically hung aluminium profiles with length up to 8 meters.

-

Pretreatment: 9-Zone chromiumfree spray-process, resulting in qualicoat quality

-

Parallell pretreatment plant for pre-anodized profiles

-

Low-temperature dryer

-

2x fully automatic powderbooths with fast colour-change system

-

IR-gel oven installed before the baking oven

-

Baking oven with energy-recovering system. Recovered energy is used for heating pretreatment and dryer

-

Double conveyor system with automatic changing points for pretreatment and powdercoating

Jungheinrch Landsberg AG, Landsberg

-

6-Zone pretreatment

-

2 off automatic powderbooths incl. 3-D system for scanning the parts to be coated

-

IR-gel-oven prior to curing oven

-

Complete ventilation-system of the total workshop, incl. re-use of energy coming out of cooling-zones and ovens

-

Extensive and complex power-and-free conveyorsystem incl. dropsections, buffers, etc. All situated on two floorlevels. Use of two different lenghts of loadbeams in order get maximum flexibility and efficiency

Reynaers Aluminium Group, Piaseczno (Poland)

Powdercoatline for aluminium profiles and sheetwork.

Design, planning and projectmanagement.

- Double line indexing pretreatment system for nano-ceramic pretreatment.

- Shape of dryer and oven adapted exactly to the available room and demands,

- Automatic powderbooths,

- According industry-standard 4.0

HF-Group, Belisce Croatia

Complete new plant for the cleaning and painting of parts for tyre-building lines. Part dimensions up to 10 mtr length and 5,000 kg.

Design, planning and projectmanagement.

- Degreasing/Phosphating with high-pressure cleaner,

- 3 off wetpaint-booths incl. paint-prep room

- Conveyorsystem incl. elevators and 2 crane-bridges

Miedema Landbouwwerktuigen, Winsum-Fr

Consultancy, engineering and projectmamangement at the expansion of a multiple line for the coating of agricultural machinery.

- Installation off 3 off cleaningbooth for HP-cleaning

-

Centrally installed pretreatment booth for degreasing, phosphatizing, rinsing and passivation.

Beth-El Industries, Haifa (Israel)

Complete new fully automated coatingplant for aluminium, stainless steel, and steel-parts. Design, planning, projectmanagement.

- Fully automatic pretreatment- and etching-line for steel, aluminium and SS

- Electroforetic dip, wetpaint and powdercoating,

- Plant is installed at several floor-levels inside the buidling,

- Complex power-and-free conveyorsystem,

- Air-supply and - conditioning-system adapted to the local climate (desert like circumstances)